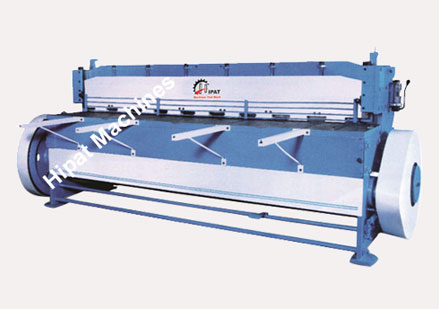

Under Crank Shearing Machine

We are one of the leading UNDER CRANK SHEARING MACHINE which is a statement in itself, these are designed through structural analysis technique which ensures scratch free production, high accuracy and repeatability. Interlock Shearing Machine which we manufacture are the most trusted and reliable machine in the market. Being one of the prime Shearing Machine Supplier in India, we know that quality assurance and customer satisfaction is a key to success for any business to grow and success.

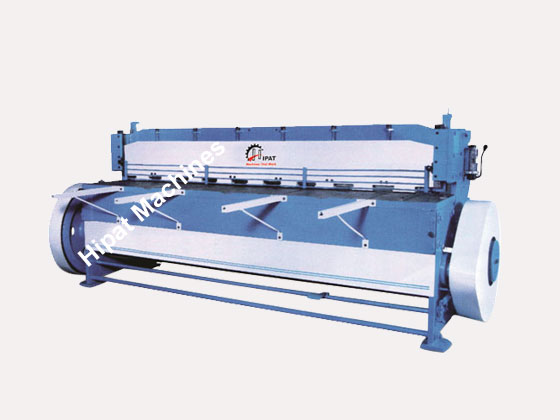

The OVER CRANK SHEARING MACHINES have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability. This Machine over Crank Shearing Machine is provided with high quality single segment knives for longer tool life. Ease in assembling knives reduces down time. The knives blades are four edged. Scale on the black gauge gives instantaneous reading of distance between shear and back gauge. Power Shearing Machine Supplier, in India we are trusted worldwide not only for the robust quality of our machines but also for the assurance of durability and a long life.

Feature

Foot pedal

Fly wheel and gear guard

Self lubrication system

Motor pulley

A pair of four edge shear blade

Standard front gauge

Black gauge manually operated

Finger guard fitted in front of hold down for operator protection

Specification

All dimensions are in mm

Power supply 400/440 volts, 3 phase, 50 cycles

Undergo stringent quality checks for easy and smooth operation

Motorized back gauge automatic lubrication system

V belts

All dimensions are in mm

Power supply 400/440 volts, 3 phase, 50 cycles

Electric Motor Starter

Stroke Counter

Hold Down Pads

PRICE: ON REQUEST

Order by Phone

0671-2505250

Shipping Information Usually dispatched With In business days.

Technical Specifications

| Model | Under Crank | |||

|---|---|---|---|---|

| HMT | U1250 | U2000 | U2500 | U3000 |

| Shearing Length MS | 1270 | 2050 | 2540 | 3100 |

| 1525 | ||||

| Shearing Thickness for MS | 3/4 | 4 | 4 | 4 |

| Size of Blades | 1270x75x 18 | 2050x75x 18 | 2540x75x 18 | 3100x75x 18 |

| No. of Segments | 2 | 4 | 4 | 6 |

| Table Size | 425 | 425 | 425 | 425 |

| Height of Table | 825 | 825 | 850 | 850 |

| Max. Back Gauge Gap | 20-500 | 20-500 | 20-600 | 20-600 |

| Max. Front Gauge Gap | 600 | 600 | 600 | 600 |

| No. of Strokes Per Min. | 50/55 | 45/50 | 40/50 | 40/50 |

| Required HP/RPM (1440) | 5 | 7.5 | 10 | 15 |

| OPTIONAL ACCESSORIES | STANDARD ACCESSORIES | APPLICATIONS |

|---|---|---|

| 1. Hydraulic Hold Down, | 1. Gear & Fly Wheel Guard, | 1. ELECTRIC PANNELS |

| 2. Automatic Lubrication System. | 2. Foot Paddle | 2. ROOFINGS |

| 3. Ball Transfer or Ball Roller. | 3. Hand Operated Back Gauge | 3. BUS BODIES |

| 4. Suitable Electric Motor | 4. Single Shot Lubrication System | 4. KITCHEN EQUIPMENTS |

| 5. Push Button Starter | 5. T-Sloted Front Gauge | 5. GENERATOR ENCLOSURES |

| 6. Portable Electro Magnetic Paddle | 6. Cutting area illuminated for clear view of blades. | 6. & Motor Pulley |

| 7. Switch Instead of Foot Paddle | 7. STAINLESS STEEL EQUIPMENT’S | |

| 8. COIL CUTTING INDUSTRIES | ||

| 9. AIR CONDITION DUCTS | ||

| 10. CONTAINER MANUFACTURING | ||

| 11. FLOUR MAKING MACHINES | ||

| 12. INDUSTRIAL STRUCTURES | ||

| 13. RAIL COACHES | ||

| 14. TIPPER TRUCKS | ||

| 15. WIND MILL MANUFACTURING | ||

| 16. TURNINE ENCLOSURES |