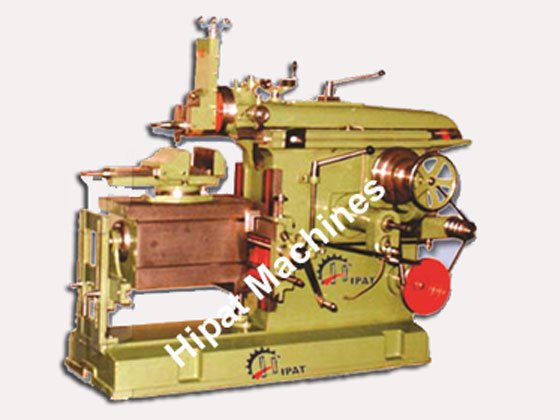

Shaping Machine

Naturally seasoned casting

Heavity cross Ribbed, Robust and sturdy construction to ensure free working

Specially designed for increase production, precision, performance and deep cut

Fully hand scrapped

Double jack system (No more digging of pits)

Clutch within easy reach of operator

Selected special alloy steel used for screws, shafts and other steel parts

Expanding ring type clutch drive in all geared machines to eliminate slippage

Graduated total slide swiveling 90 degrees either way

HIPAT shaper for a deep cut-high metal removal & sustained accuracy

Accuracy plus simplicity is the compact of HIPAT SHAPER

PRICE: ON REQUEST

Order by Phone

0671-2505250

Shipping Information Usually dispatched With In business days.

Technical Specifications

| MODEL | HS12 | HS18 | HS24 | HS30 | HS36 | HS40 |

|---|---|---|---|---|---|---|

| Maximum working stroke | 14” | 20” | 26” | 32” | 37” | 42” |

| Length of ram without tool slide | 30” | 40” | 53” | 60” | 66” | 75” |

| Ram bearing in column | 20” | 26” | 31” | 37” | 41” | 44” |

| Ram bearing width | 7.5” | 10.5” | 12” | 12.5” | 12.5” | 14” |

| Tool Slide Traverse | 5” | 6” | 8” | 9” | 10” | 11” |

| Maximum distance from table to ram | 14” | 15” | 16” | 18” | 20” | 24” |

| Maximum distance from table to ram | 2” | 2” | 2” | 2” | 2” | 3” |

| Horizontal traverse of the table | 16” | 20” | 26” | 30” | 32” | 36” |

| No of speed | 3 | 3 | 4 | 4 | 4 | 4 |

| Length and width of cross slide | 25”*10.5” | 31”*11” | 38”*12” | 43”*12.5” | 46”*12.5” | 51”*15” |

| Top clamping surface of table | 14”*11” | 18.5”*12” | 25”*15” | 31”*16” | 37”*18.5” | 40”*20.5” |

| Size of base plate | 40”*16.5” | 50”*22” | 64”*23” | 76”*24” | 82”*26” | 90”*30” |

| Power required | 1 H.P. | 2 H.P. | 3 H.P. | 5 H.P. | 5 H.P. | 7.5 H.P. |

| Approximate net weight | 1200 kg. | 1500 kg. | 2000 kg. | 2300 kg. | 3200 kg. | 4000 kg. |

| OPTIONAL ACCESSORIES | STANDARD ACCESSORIES | APPLICATIONS |

|---|---|---|

| 1. ELECTRIC MOTOR | 1. SWIVELLING VICE | 1. Automobiles |

| 2. LUBRICATION | 2. CRANK HANDLE | 2. Die & Mould Manufacturers |

| 3. AUTOMATIC TOOL LIFTING | 3. MOTOR PULLEY | 3. Aerospace |

| 4. ALL GEARED MACHINE | 4. MOTOR BASE | 4. Medical Equipment |

| 5. KEY WAY CUTTING ATTACHMENT | 5. TOOL KIT | 5. Textile Machinery |

| 6. Diamond & Jewellery Industries | ||

| 7. Allied Machinery | ||

| 8. Plastic Processing Machinery | ||

| 9. Defence |