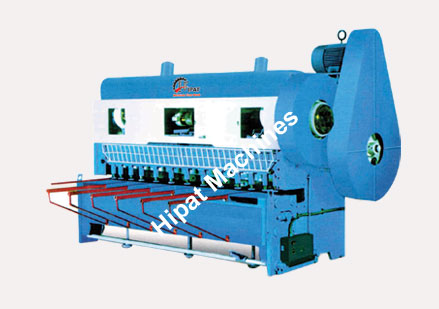

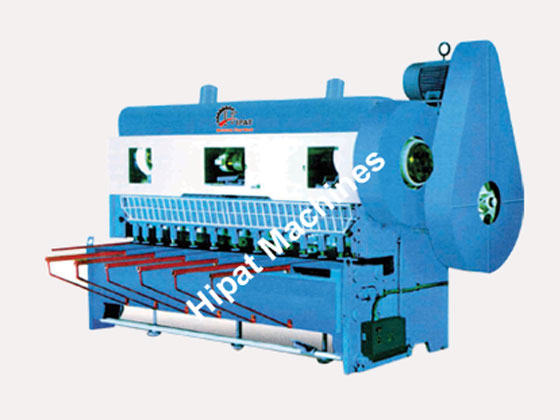

Over Crank Shearing Machine

Rigid, Interlock designed, heavily welded construction of MS plates and sections to take full load with minimum deflection. The arm is guided throughout its length by fiber guideways ensuring proper clean cut. A rigid clutch mechanism is provided for giving continuous strokes for production.

The spring loaded Mechanical Hold Down maintains a positive and uniform pressure along the full length of work piece avoiding slipping and bowin of sheet resulting a clean square cut.

HIPAT Shears are provided with four edge rectangular high quality High Carbon High Chromium (HCHC) knives for longer life. Gun Metal Bushes are provided in all running parts. A rigid and accurate mechanical back gauge & hand operated Single Shot Lubrication system is provided with all HIPAT shears as standard equipment.

PRICE: ON REQUEST

Order by Phone

0671-2505250

Shipping Information Usually dispatched With In business days.

Technical Specifications

| Model | Over Crank | |||||

|---|---|---|---|---|---|---|

| HMT | O1250 | O2000 | O2500 | H2000 | H2500 | H3000 |

| Shearing Length MS | 1270 | 2050 | 2540 | 2050 | 2540 | 3100 |

| 1525 | ||||||

| Shearing Thickness for MS | 6/8 | 6/8 | 6/8 | 10/12 | 10/12 | 10/12 |

| Size of Blades | 1270×75 x23 |

2050×75 x23 |

2540×75 x23 |

2050×100 x23 |

2540×100 x23 |

3100×100 x23 |

| No. of Segments | 2 | 4 | 4 | 4 | 4 | 6 |

| Table Size | 425 | 425 | 425 | 425 | 425 | 425 |

| Height of Table | 800 | 800 | 800 | 800 | 800 | 800 |

| Max. Back Gauge Gap | 20-500 | 20-600 | 20-600 | 20-600 | 20-600 | 20-600 |

| Max. Front Gauge Gap | 600 | 750 | 750 | 750 | 750 | 750 |

| No. of Strokes Per Min. | 40/35 | 40/35 | 40/35 | 35/30 | 35/30 | 35/30 |

| Required HP/RPM (1440) | 10 | 15 | 20 | 25 | 25 | 30 |

| OPTIONAL ACCESSORIES | STANDARD ACCESSORIES | APPLICATIONS |

|---|---|---|

| 1. Hydraulic Hold Down | 1. Gear & Fly Wheel Guard | 1. ELECTRIC PANNELS |

| 2. Sheet Bending Unit | 2. Foot Paddle | 2. ROOFINGS |

| 3. Ball Transfer or Ball Roller | 3. Hand Operated Back Gaug | 3. BUS BODIES |

| 4. Suitable Electric Motor | 4. Single Shot Lubrication System | 4. KITCHEN EQUIPMENTS |

| 5. Push Button Starte | 5. T-Sloted Front Gauge | 5. GENERATOR ENCLOSURES |

| 6. Portable Electro Magnetic Paddle | 6. & Motor Pulley | 6. STEEL TANKS |

| 7. Switch Instead of Foot Paddle | 7. STAINLESS STEEL EQUIPMENT’S | |

| 8. COIL CUTTING INDUSTRIES | ||

| 9. AIR CONDITION DUCTS | ||

| 10. CONTAINER MANUFACTURING | ||

| 11. FLOUR MAKING MACHINES | ||

| 12. INDUSTRIAL STRUCTURES | ||

| 13. RAIL COACHES | ||

| 14. TIPPER TRUCKS | ||

| 15. WIND MILL MANUFACTURING | ||

| 16. TURNINE ENCLOSURES |