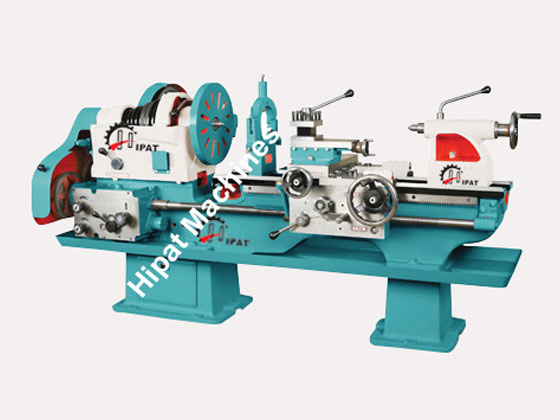

Heavy Duty Lathe Machine

“HIPAT” CENTER LATHES are well suited for all common turning surfacing and screw cutting operation with accuracy conforming to nearby grade –1 limits. These heavy duty lathe machines are specially designed for continuous light and heavy duty job and to give prolonged efficient life these lathes are worthy of a place in every machine shop where economy of operation, precision and reliability are primary considerations.

THE BED is made of close grained cast iron, having unusual strength and long wearing qualities it is machined and ground to finish and is well bracked to withstand vibration free operation, under heavy cutting load the casting are fully seasoned and removal gap piece is fixed.

HEAD STOCK:- The flat seat of headstock over the bed is perfectly matched by precision hand scrapping. Its spindle is made from high carbon steel which rotates on two cylindrical split type gun-metal bushes of grade 1 composition both at the front and at the back for smooth running and perfect balancing the machines are also made with headstocks fitted with tapper roller thrust bearings. During the operation of the machine eight different feed movements can be arranged by means of specially constructed four step cone extraction V-Belt gear mechanism. The headstock gears have HELICAL HOB-CUT TEETH.

THE APRON is of double well design with independent drive motion for feeds and screw cutting simultaneous arrangement of feed and screw cutting is prevented by an interlock mechanism.

THE TAIL STOCK is of special and sturdy design, it is guided inverted ‘V’ and flat way bed independent of the saddle guides and has on off setting device for tapper turning.

THE SADDLE is of heave design for stable rigid longitudinal movement. A compound rest accurately graduated is mounted on the saddle for conical turning and can be swiveled on either side. A revolving four way steel tool post is provided. The rack is of steel with machine cut teeth.

PRICE: ON REQUEST

Order by Phone

0671-2505250

Shipping Information Usually dispatched With In business days.

Technical Specifications

| MODEL | RANGE | A.B.C | WEIGHT (Approx) |

Floor L |

Space W |

Occupied | |

|---|---|---|---|---|---|---|---|

| HGT-5 | 5.5 FEET | 1675 MM | 550 MM | 1100 KG | 1980 (78″) | 1250 (49″) | 1370 (54″) |

| HGT-6 | 7 FEET | 2130 MM | 1000 MM | 1300 KG | 2425 (95″) | 1250 (49″) | 1370 (54″) |

| HGT-9 | 9 FEET | 2740 MM | 1560 MM | 1500 KG | 3050 (120″) | 1250 (49″) | 1370 (54″) |

| HGT-10 | 10 FEET | 3048 MM | 1860 MM | 1700 KG | 3350 (132″) | 1250 (49″) | 1370 (54″) |

| HGT-12 | 12 FEET | 3658 MM | 2450 MM | 1925 KG | 3950 (156″) | 1250 (49″) | 1370 (54″) |

| OPTIONAL ACCESSORIES | STANDARD ACCESSORIES | APPLICATIONS |

|---|---|---|

| 1. Electric Motor & Starter | 1. Face Plate(One) | 1. TOOL ROOMS |

| 2. Electric Coolant Pump | 2. Chuck Plate(one) | 2. TOOL & DIE MAKING |

| 3. 4jaw independent chuck | 3. Centers(Two center adapter(One) | 3. PRECISION MANUFACTURING |

| 4. 3jaw self centering chuck | 4. Stationery steady(One) | 4. EDUCATIONAL INSTITUTES |

| 5. Gears to cut metric threads | 5. Follow Rest Assembly(One) | |

| 6. Taper turning attachment | 6. Set of 22 change | |

| 7. Tool post grinder | 7. Gears (One) | |

| 8. Double Gap or Triple Gap etc. | 8. Motor Plate (One) | |

| 9. DIGITAL READ OUT (DRO) | 9. TOOL BOX | |

| 10. REVOLVING CENTRE | 10. INSTRUCTION MANUAL | |

| 11. NORTON GEAR BOX |